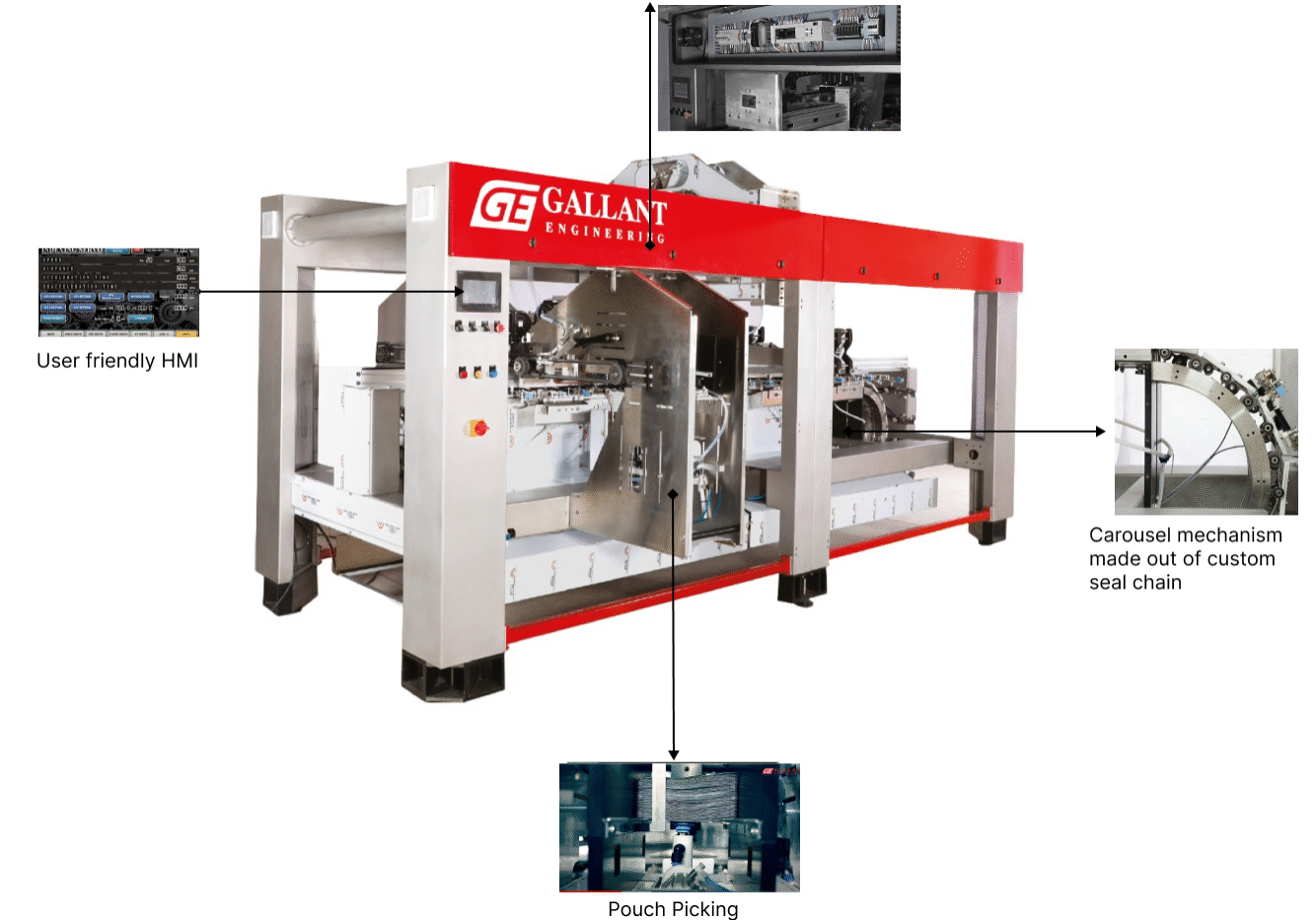

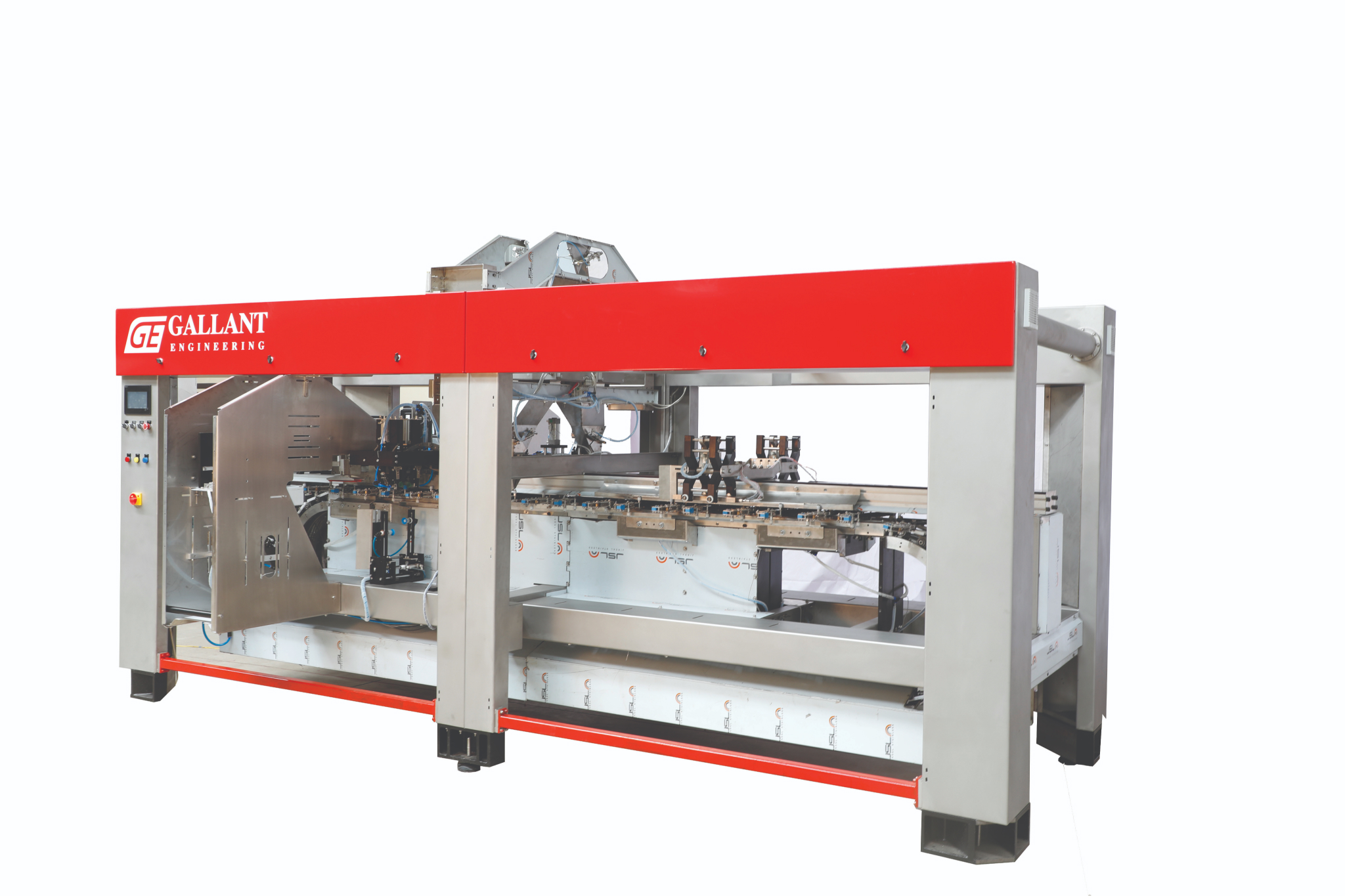

High Performance Li-Pack Series comes in single lane dual lane. Our dual lane, Patent Pending, Performance Series Machines offer high output-to-cost ratio.

Horizontal Premade Pouch Machine

Ensures precise and efficient packaging

Patent-Pending Technology

Incorporates our latest innovations for superior performance

Auto Changeover

Easily switch between different pouch sizes with a push of a button from the HMI screen

High Speed

The dual lane machine, Li-Pack 360 D, can achieve mechanical speeds of up to 5400 pouches per hour

Unique Pouch-Picking Assembly

Supports vertical stacking of pouches, which is more effective than traditional horizontal layouts

Precision Indexing

Maintained for life with our custom sealed chain that requires no external lubrication

One-Filler Two-Lanes

Single Multi-head scale can be used to feed both lanes with the use of diverter assembly

Reliable Pouch Opening

Servo operated fork assembly ensures efficiency in pouch opening and filler nozzle insertion

Superior Zipper Opener

Use of mechanical fingers ensures opening of zippers efficiently

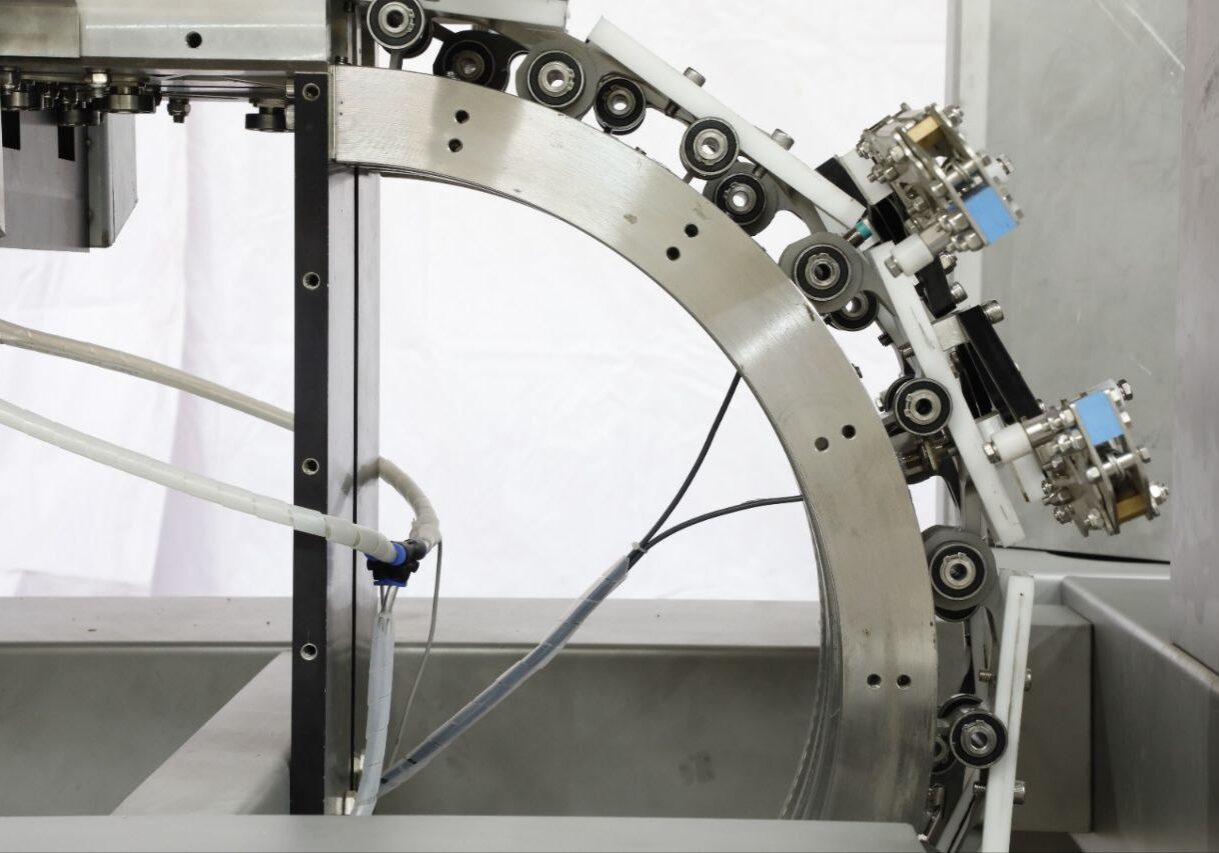

Carousel Mechanism made up of Custom Sealed Chain

Common Issues |

Our Solution |

|---|---|

| Chain Stretch | Innovative custom sealed |

| Loss of Precision | Stretch-Free Design: Maintains precision and reliability throughout its lifespan |

| Durability Concerns | High quality SS bearings |

| Maintenance Efforts | Automated Lubrication: Ensures smooth and consistent operation without manual intervention |

Carousel Mechanism made up of Custom Sealed Chain

Chain driven Carousel Indexing Mechanisms are very well known for accuracy and flexibility. Over a period, chain stretches due to tension, wear and tear and the precision indexing ability is lost. This problem is solved by our in-house manufactured custom sealed chain. This chain is sealed for life and hence no external lubrication is required for it.

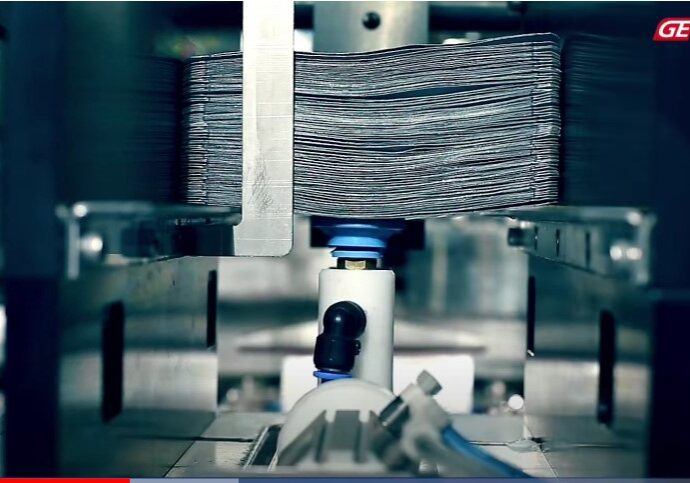

Pouch-Picking Assembly

- Simple and Efficient Design.

- Pouch Pick Up and Opening: Our assembly ensures a seamless and efficient process for pouch picking and pouch opening.

- Unique Vertical Stacking: Unlike traditional staggered horizontal layouts, our unique pouch picking assembly supports vertical stacking of pouches. This method is more effective and space-efficient, allowing for smoother operations and better organization.

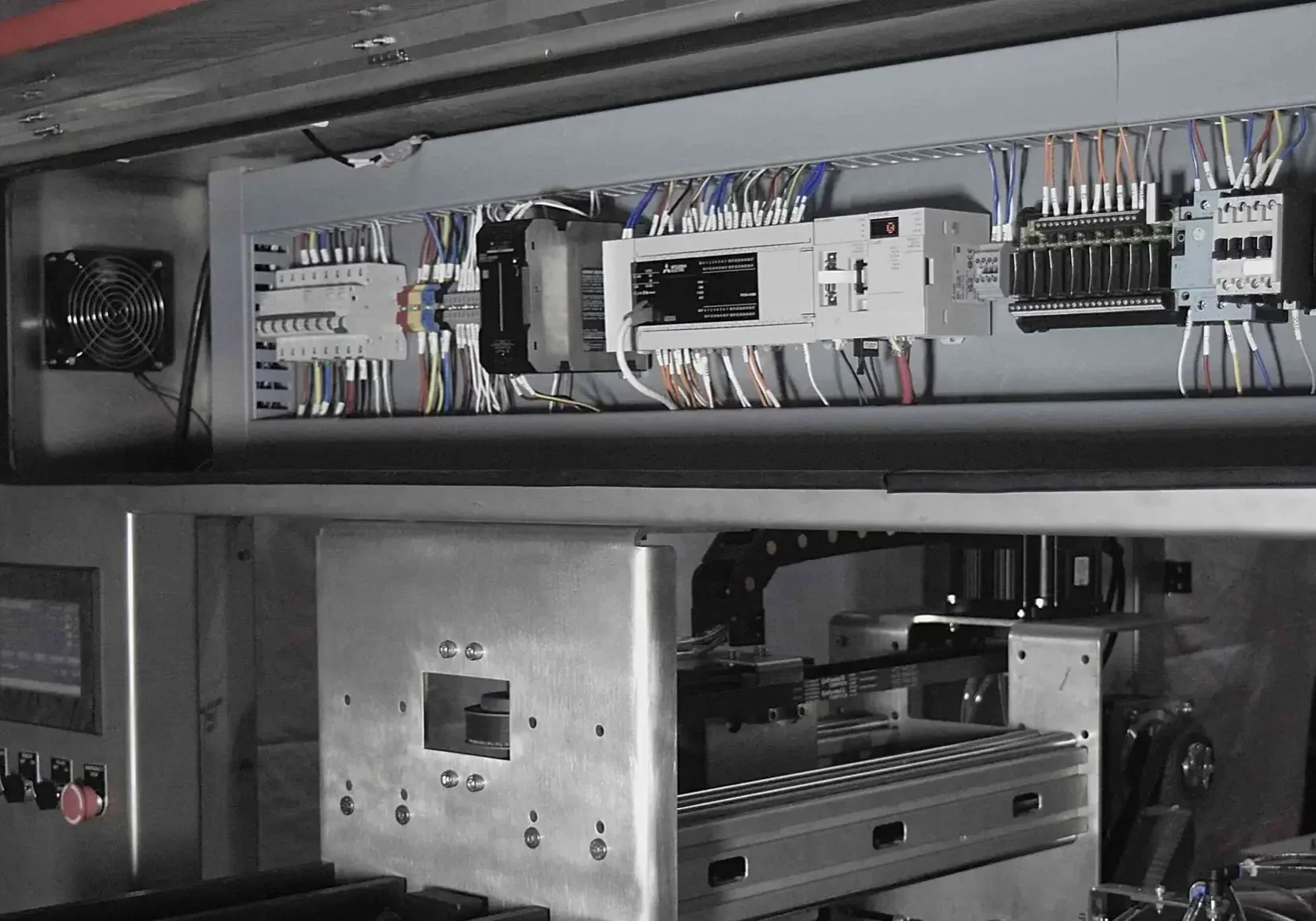

Stainless Steel Frame

- Heavy-Duty Construction: Our machine features a durable stainless-steel frame, shot-blasted for effortless cleaning

- Thoughtful Design: Easy access from all sides ensures convenient maintenance and operation

- Integrated Components: Built-in electrical panels and an integrated HMI enhance functionality and streamline the user experience

Concealed Electrical Panel

Easy assess to electrical panels for troubleshooting and maintenance if needed

Trusted, User-Friendly HMI from Mitsubishi

Li-Pack Series are equipped with Mitsubishi HMI. These HMI offers high reliability for easy operation. Its software is very user friendly and easy to understand for operating team.

Sealing Station

Our Machines come with standard Pneumatic heat-sealing assembly. Some other options which can be provided to the assembly are ultrasonic and servo operated sealing assembly.

Explore Gallery

Our machine is compatible with all fillers and

premade pouches