Exhausted with your CAM-Based Rotary Machine?

Our RT series runs on state-of–the art servo operated and pneumatic mechanisms which eliminates most problems caused by a traditional CAM driven Rotary machine. It allows us to do control indexing precisely and gives more flexibility in the machine. This advanced technology ensures reliable and consistent performance, minimizing downtime and operational challenges.

Key Features:

- Robust Construction: Built with high-quality stainless steel and aluminium, the RT Series is designed for durability and hygienic operation.

- Advanced Indexing: Our unique racetrack indexing assembly, featuring a custom-sealed stretch-free chain, delivers precise and efficient pouch movement.

- Optimized Pouch Feeding: The stacked pouch in-feed system maximizes productivity compared to traditional staggered pouch methods.

- Reliable Sealing: Standardized pneumatic sealing ensures consistent and high-quality seal integrity.

- Innovative Pouch Opening: Our unique zipper/pouch opening mechanism enhances operational efficiency.

Interface: The intuitive - machine interface and software settings simplify operation and adjustments.

- Smaller footprint: Our compact design pans up to just 4.5m² and helps optimize floor space.

- Easy Maintenance: The conveniently located electrical panel facilitates troubleshooting and maintenance.

- Easy changeover in minutes.

The RT Series bagger combines precision engineering with user-friendly operation, delivering exceptional performance and value.

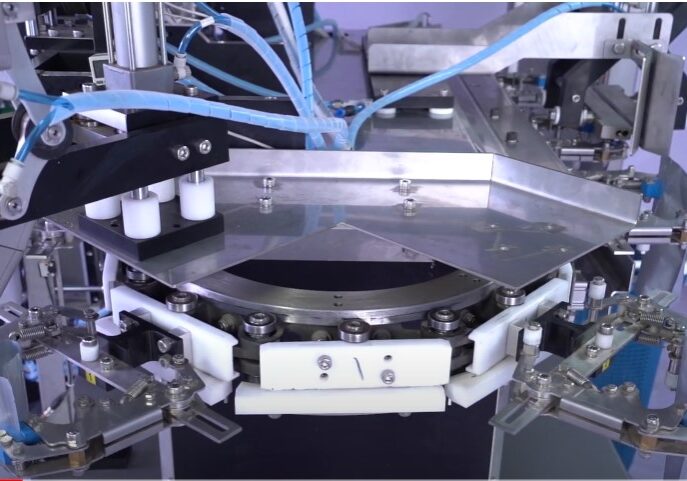

Racetrack Mechanism

Racetrack’ indexing assembly is made up of custom sealed stretch-free chain which is designed and manufactured in house.

Innovative and Efficient Pouch Pick up Assembly

The in-feed to the machine is in the form of ‘Stacked Pouches’, which is more efficient, compared to traditional staggered pouches. The efficient pouch sorting eliminates the need for a conveyor belt to hold staggered pouches and hence helps to keep a smaller footprint.

Standardized pneumatic operated Sealing Assembly

Heat Sealing assembly has thermocouples on both sealing bars. The pneumatic cylinder helps to control sealing pressure and ensures efficient pouch sealing.

Unique Zipper / Pouch Opening Mechanism

Efficient servo operated mechanism for precise motion control with integrated zipper opening

Easy to use Machine Interface And Software

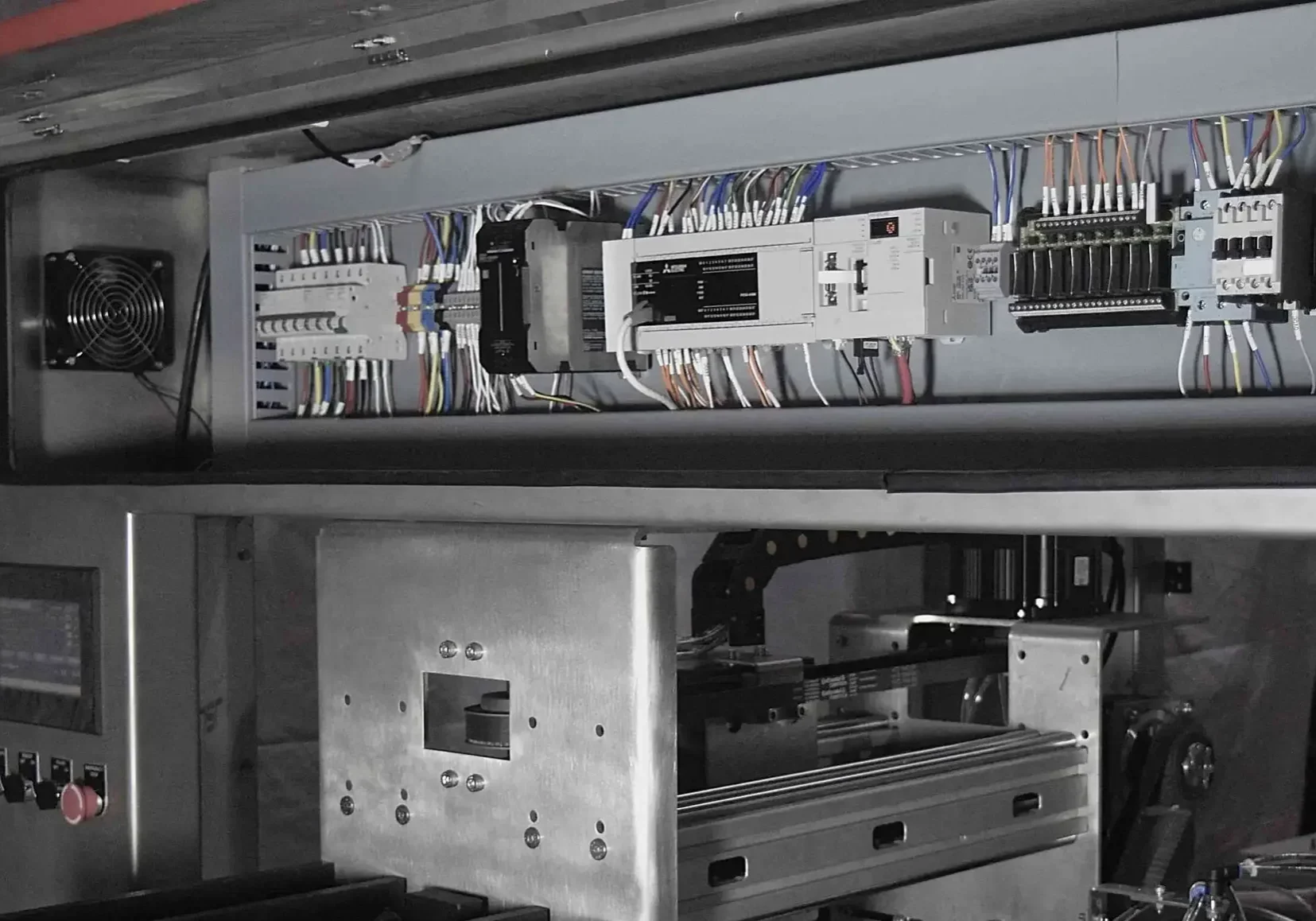

RT-Pack Series are equipped with Mitsubishi HMI . These HMI offers high reliability for easy operation. Its software is very user friendly and easy to understand for operating team.

Convenient electrical panel

Convenient electrical panel that is easily accessible for trouble shooting and maintenance

Gallery

Our machine is compatible with all fillers and

premade pouches