Packaging pouches on the Premade Pouch Machines is a growing trend due to its versatility in handling various types and sizes of pouches. Premade Pouch Machines are also a cost-effective alternative to standard Horizontal Form Fill Seal (HFFS) machines.

Our Machines are equipped with the latest servo technology which enables them to reliably and efficiently fill and seal all types of pre-made pouches. The unique and innovative mechanisms help conduct all the operations on the machine smoothly and efficiently.

High-performance Li-Pack Series

High-performance Li-Pack Series

Key features

- Linear Horizontal Premade pouch machine

- Auto changeover to different pouch size with a push of a button from HMI screen

- Patent pending technology.

- High Output of up to 5400 pouches per hour can be achieved for Dual Lane versions

- Unique pouch picking assembly supports stacking of pouches vertically which is more effective than the traditionally staggered horizontal layout pattern.

- Precision indexing ability is maintained for life due to the in house manufactured custom sealed chain. This chain does not require external lubrication

Compact RT-Pack Series

Compact RT-Pack Series

Key features

- Racetrack Horizontal Premade pouch machine

- Advanced mechanisms using servo and pneumatic systems

- Custom Sealed Chain for stretch free Racetrack design indexing assembly

- Compact footprint of 4.5 sq.m.

- Unique pouch picking assembly supports stacking of pouches vertically in a magazine

- Ergonomic design with access to machine from all sides for efficient machine operation

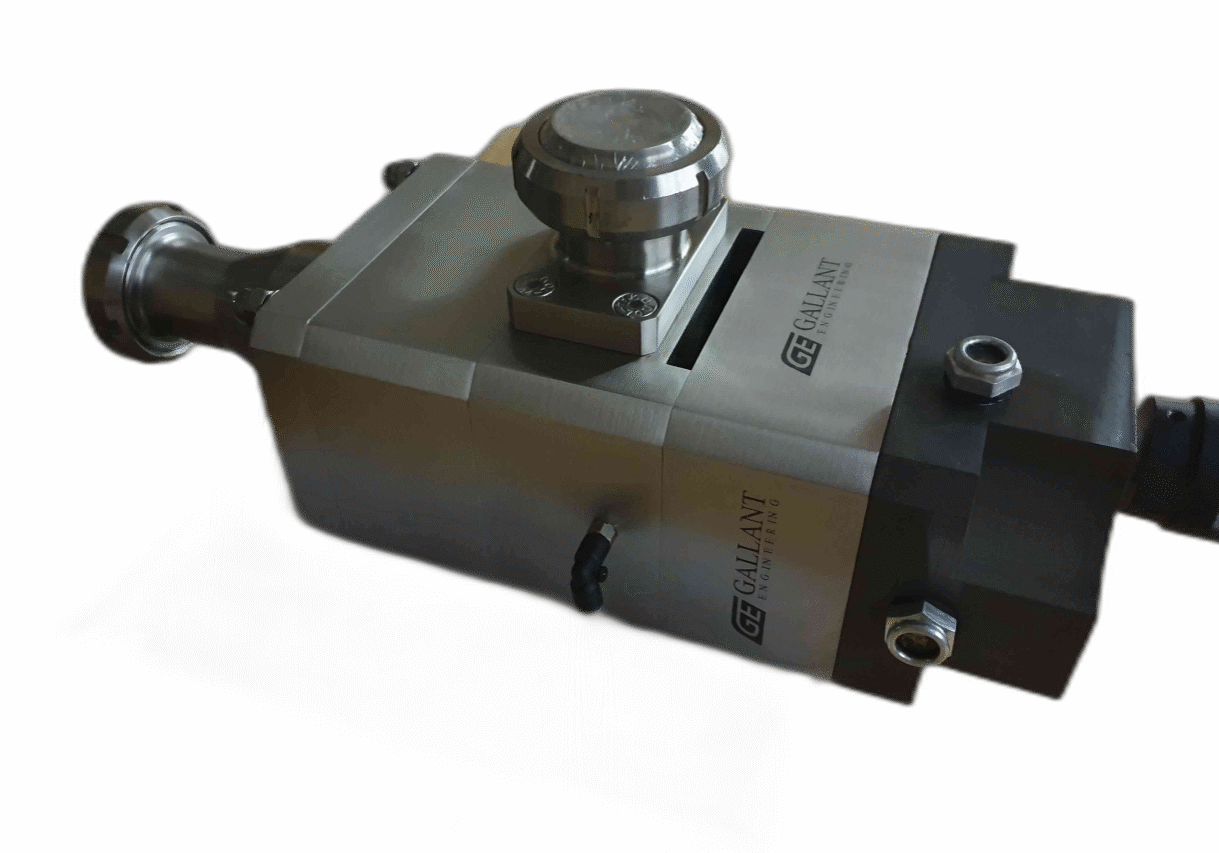

Roto-fill technology

Roto-fill technology

Key features

- High speed and high temperature filling

- Easy adjustment of the quantity to be filled through HMI

- Extremely efficient

- Compact design possible

- Easily cleanable

Our Customers in USA:

Delivering reliable, efficient and innovative solutions to our esteemed customers worldwide

Our Customers in India:

Delivering reliable, efficient and innovative solutions to our esteemed customers worldwide

Our Partners and Distributors

Partnering with Industry Leaders